From a breakthrough in the 90s to one of Denmark's most well-known shoe brands: “Girls went straight from Buffalo to Billi Bi, as we experienced it"

This is a translation. Read the original version in Danish here.

The first thing you meet is a wall of shoe boxes. Charcoal grey, rectangular blocks stacked on top of each other like a kind of gate one has to pass through. On each box, at the top left corner is written in embossed gold lettering: Billi Bi.

We are in a town called Elda, outside Alicante in Spain, at the entrance to the factory where the brand has produced a large part of their shoes since the mid-90s. A small, family-owned factory where all shoes are crafted by hand. Where specialized craftsmen each have their own station where they bring the design ideas of CEO and owner Carsten Friis to life; a ballet flat in blue denim with a black patent toe and bow. A pair of Mary Janes in shiny silver-painted leather. Classic black suede pumps with a pointed toe. Black leather loafers with a gold buckle. Or one of the many other models produced each year at the factory in the hands of those who know their craft inside out. Like the one cutting out the leather. Precisely and determined, he cuts around the paper template on the thick leather with a small, hooked knife before the cut pieces move on to the territory of the seamstresses. Here, the indistinguishable pieces are assembled like a puzzle that seems almost unsolvable for outsiders. The pieces are sown, glued and stamped at tables filled with drawings, tools, rolls of ribbon, and old jam jars, now leading a second life as containers for homemade glue. It is almost quiet, except for a discrete but constant hum of repetitive work mixed with the sound of fans relieving the pressure from the already heavy Spanish May heat. On shelves, stacked soles come in all shapes. Square, round, or pointed toes. Low or high heels. Throughout the factory runs the massive, old iron frame connecting each station and guiding the shoes around the facility before they end up at the final station; the man who, with lightning-fast movements, packs them in layers of black tissue paper in their own grey shoe box.

“Yes, I guess we’re a fairly well-kept secret in that way,” says Carsten Friis when I ask him why Billi Bi hasn’t put more emphasis on this story. The story of how, from the beginning until today, the brand produce all the shoes by hand in this factory. Because I think most of us have been acquainted with Billi Bi at some point in our lives — but I also believe that very few of us associate the brand with that in particular.

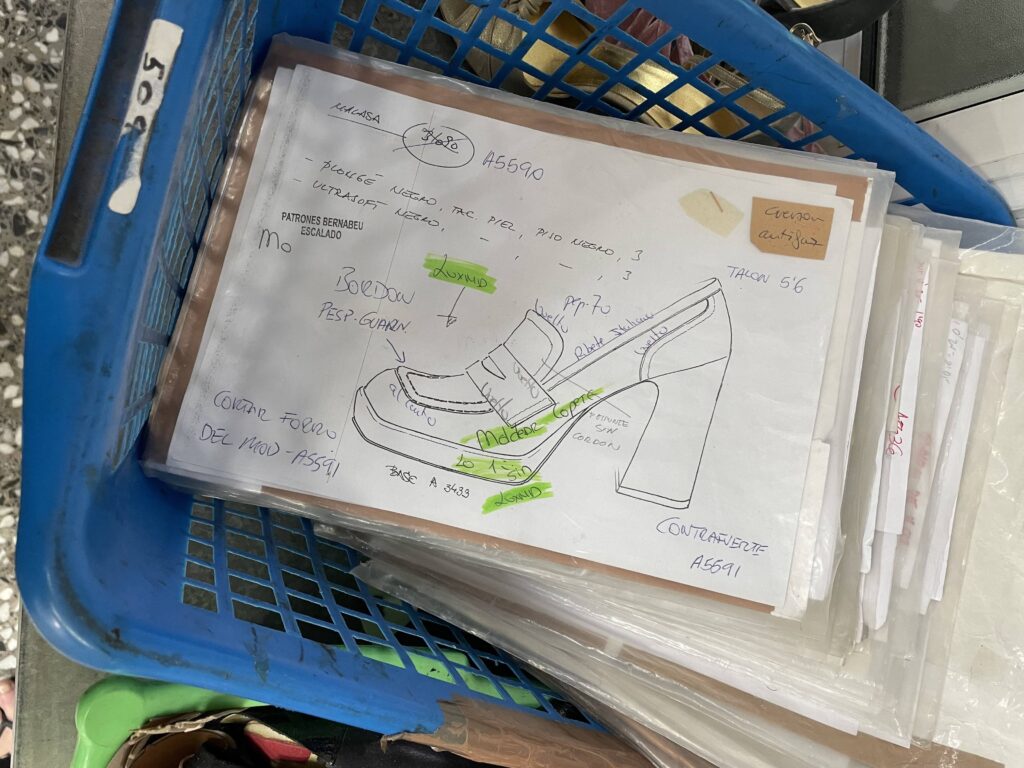

“I don’t think our customers know. We’ve tried to highlight it on our website and in our marketing efforts, but I don’t think people are really aware of how much work goes into each shoe,” he continues, when we half an hour later stand inside a small office in the other end of the factory. This is where all meetings take place, where collections are thought out, drawn, and refined. It feels like stepping into a time capsule. Everywhere are hand-drawn sketches of new shoe designs that could be from the 70s, 90s, or whatever sort of nostalgia is now trending. Measuring tapes, colour charts, fabric samples, and small white plastic containers with buckles. Wide shelves with shoes either being worked on or ready to go into production.

Here, too, sits Mercedes, who runs and owns the factory, with her adult daughter, Maria, who grew up among shoe boxes, soles, and lasts. She knows the place like the back of her hand, which was evident when she, as part of her ongoing management takeover from her mother, showed us around the factory before and explained all the technical details in the best English she has learned. And that practically no one else in the factory speaks.

“One of the best things about my job is visiting the factories,” says Carsten Friis, continuing:

“The employees have been here for half a lifetime, so I know them all very well. The one standing at the belt. The one handling the heels. And then there’s the craftsmanship, which is so fascinating. To see something I’ve designed being created in their hands. And then seeing someone walking the down street wearing the shoes as well —then I couldn’t be more proud.”

Three decades in

Billi Bi turns 30 this year, but the company’s history goes further back. Way back. To 1936, to be precise, where the couple Søren and Evelyn Friis began producing children’s shoes in an old stable in Copenhagen’s Nordvest district under the name Fransi. The company quickly grew and expanded to women’s shoes before the next generation, their son Carl Friis, joined the business in the 1960s after graduating as a designer and modelist at Ars Sutoria in Milan. Today, the third generation, Carl’s son, Carsten Friis, is at the helm. He started working for the company in 1989 while studying economics and law at CBS. But in 1993, he entered the family business for real. Along with his father, he founded the sub-brand Billi Bi with a vision of creating fashionable shoes for young women. It began with just six pairs of shoes that Carsten designed and put into production at the then brand-new factory outside Alicante. The same year, he travelled there for the first time with his father to launch the small debut collection of Billi Bi shoes.

“I don’t want to travel anymore, so now you take over,” the father said a few years later to Carsten and Jens Schøtt, who had joined the company as a Sales Manager in 1997, when the three of them were on their way back to Denmark after another trip to the factory. And so they did. Today, they are still the duo behind Billi Bi. Jens Schøtt as COO and the one sketching every shoe design —alongside designer Josefine Meisner. A discipline he learned from Carl Friis, who spotted his talent and encouraged him to pursue it. And Carsten Friis as CEO, autodidact designer, and third-generation owner.

The man who, with lightning-fast movements, packs each pair of shoes before leaving the factory.

Today, Billi Bi is one of Denmark’s most well-known shoe brands with two concept stores and 17 employees at the headquarters in Kokkedal. In other words, a company that, in many ways, has kept up with the times — except for the handcrafted shoes, which, let’s be honest, are a rare thing in their price range, usually ranging from 1000 to 3000 kroner. And it’s hard not to wonder how Carsten Friis has managed and chosen to hold onto such a costly principle in an industry so affected by inflation, expensive raw materials, energy prices, and generally cautious consumers, as the fashion industry.

“I believe, that the secret to our continued success is value for money. It’s a tough balance striving for the highest quality at a price that isn’t too exclusive. And we constantly work on striking that balance because it has always been and still is crucial for us that the craftsmanship is at the highest level,” he explains when we later that day talk about the crisis that has flooded the fashion industry. A crisis that he expects will effect Billi Bi as well.

Although the company Fransi A/S, owner of Billi Bi’s wholesale business, showed positive progress in the 2022 annual report, it also indicated an anticipated decline in 2023. “We can definitely feel how inflation and increased living costs are causing people to hold back,” Carsten explains also noting the shift in consumer spending towards experiences and travel. All at the expense of fashion.

For this reason, the company is currently exploring alternative options in Elda – despite its close connection to the aforementioned factory. Other factories that can deliver a slightly more affordable product by using different techniques and methods. This primarily applies to specific models though, some ballet flats that the brand is “spitting out” this year and that Carsten Friis expects them to be next spring as well. It’s not all products that he would entrust into new hands, and it’s still uncertain whether such new products will live up to the high standards of his experienced eye. “Time will tell,” as Carsten Friis puts it himself emphasising also his feeling of responsibility towards the original factory and his intention to only pursue an alternative when the old one is fully engaged. Because it’s become “like a second family that factory.” A factory his father initiated the collaboration with and he himself has spent the last three decades tying strong bonds with – just like another branch in the family tree of Billi Bi that cannot be disconnected just like that.

From Buffalo to Billi Bi

When taking over a family company there is a natural urge to preserve old traditions. But there are some areas in which you just can’t insist on keeping status quo. Responsibility for example. For this reason Billi Bi this day only use leather certified by the Leather Working Group, who aims to improve the value and supply chain for leather production, reducing water, energy consumption, and chemicals. However, this is a process without a definite endpoint, just like it is for every other company in the fashion industry today. An industry that has undergone significant changes over the past 30 years. Not just in terms of materials and social responsibility. But also in terms of its pace, technology and the expectations of the consumer.

“I think it’s safe to say, that there are other industries easier to operate in than the fashion industry. Industries that are more stable and that doesn’t expect you to reinvent yourself twice a year. That’s what stresses me out the most – you always have something to live up to,” Carsten Friis says the next day, when we sit on the rooftop terrace of the hotel in Alicante. He and Jens Schøtt found a spot in the sun for putting together the last pieces on their next collection. Different colour charts are spread out on the table between them representing next season’s palette.

Together they’ve travelled every other week since March. Alternate between Alicante and Portugal, where they also have a long-standing collaboration with a factory and have an equally big and established production setup. Both have mainly shoes on their minds during the four or five days they spend at the factories many times a year. “We dream about shoes when we’re here,” as Jens Schøtt puts it from the other side of the table. He adds:

“Yes, and the industry has also changed in the way that now everything is allowed. When we first started, if something was in, everyone would wear it. No matter who you were. And that meant, that you as a company could create a huge revenue on only two or three different shoe designs. As long as you were able to hit that specific look of the season. Now, everyone has their own unique style. And that’s okay. But it also means that you need to cater to a way bigger and wider audience. And that’s of course a lot harder.”

And it actually was with only two designs that Billi Bi got their first big break through back in the fall of 1996. Two pairs of boots to be specific, that were “genius,” as Carsten Friis puts it himself.

Because they fit perfectly in the beginning demand for something a bit more dressy, which hit the industry in the mid-nineties as a contrast to the famous Buffalo era.

“One boot was three-quarter length, had a chunky six centimetre block heel and a very distinctive, square toe. It cut the leg in a way that fit right in with the style that fall, and we were lucky that no one else offered that type of boot. So the girls more or less went from Buffalo to Billi Bi as we experienced it. And that definitely helped kickstart our success and put our brand on the map. Afterwards we of course just tried to build on that success,” says Carsten Friis who according to himself stay up-to-date as a designer by travelling, visiting fashion fairs all over world, having conversations with people of all age groups and by naturally keeping a close eye out for what’s going on withing fashion in general. Not to mention using his many years of experience.

“When you, like me, have been doing this for 30 years, you really experience how fashion is a loop, and just how many trends return, that we’ve already made one version of before. So of course we use our history in our work and to analyse why this and that shoe model sold well, and how we can bring it up to date in a new version,” Carsten Friis says. To the question what his dreams are for Billi Bi in the future, he quickly replies USA.

“It’s something I hope we can initiate within the next couple of years. Establishing a setup over there,” he says explaining that the plan is to create a local office and then delegate to a distributor or agent. But why now, one might ask?

“We always get a lot of interest from the states when exhibiting on different fairs, telling us that the brand would fit right in on the American market,” Carsten Friis says before leaving his final remark:

“I just really want to continue expanding Billi Bi’s position on the market – and now we are so well represented in Europe, USA seems like a natural next step.”